Using Aquaculture and aquaponics in agriculture to ensure sustainable food, environmental protection, waste reduction, green alternatives and best rewarding

Monday, August 30, 2010

Farmers Blame Problems On Fry Imports

To make matters worse, the fish have grown to more than 30 centimetres in length, more than twice the maximum marketable size of 10 to 13 centimetres, according to New Straits Times.

And, the bigger fish consume large quantities of expensive feed pellets which cost between 90 ringgit (MYR; S$38.68) and MYR112 per bag of 20kg.

"We are in a quandary as the maximum-sized fish fry normally fetch between MYR1 and 1.20 each. We cannot sell at that price now since the fish had grown so big and it cost so much to feed them," said farmer Ibrahim Muhammad.

He said there were more than a million fish that were past the marketable size in the two villages.

"Two months ago I had to sell 100,000 fish measuring around eight centimetres at 35 sen each to a wholesaler as I did not want them to add to the number of overgrown fish in my ponds. We are worried that the fish will soon die from lack of oxygen as the stagnant water in the ponds only have enough oxygen for small fry."

He said there were rumours that smuggled fish fry from Thailand, which sold at below market price had caused the demand to drop.

Another fish fry farmer from Kampung Keluang, Azmi Ismail, said he had more than 30,000 fish that had grown more than 10 centimetres in his 11 fish ponds.

"The market has dropped and there is no news from the usual wholesalers," he said, adding that he had not been able to sell anything since February.

He said he had to fork out about MYR1,000 every month to feed the fish and the cost would increase as the fish grow in size.

State Fisheries Department director, Zakaria Ismail, said they would try and help the farmers.

He said the department was finalising the quotations for wholesalers to buy the fish fry before supplying them to aquaculture farms.

"We will buy hundreds of thousands of fish fry through the wholesaler that has the best bid."

He told New Straits Times that he had not received any complaints about smuggled fish fry from Thailand but gave an assurance that all fish fry going through the Customs, Immigration and Quarantine points along the Malaysia-Thai border would be subject to stringent screening.

"Aquaculture farms risk getting unhealthy fish fry if they opt for smuggled fry," he said.

By courtesy of www.thefishsite.com

Saturday, August 28, 2010

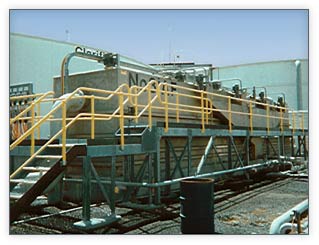

Aquafloat

Aquafloat Induced Air Flotation (IAF) aerators & associated plant from PCPL provide an efficient & cost effective air flotation system for the removal of fats, oils, greases and other solids from industrial & municipal water and wastewater.

Thursday, August 19, 2010

Aquaculture Aeration

Since a majority of all aquaculture problems, including disease, are caused by poor water quality and, in turn, most water quality problems can be resolved with proper aeration (oxygenation), it is clear that aeration plays a crucial role in this process.

Oxygen is the main limiting factor in both recirculating and traditional aquaculture systems. Less than the required levels lead to poor water quality, poor feed conversion ratios (FCR), reduced growth and increased mortality. With high energy prices, energy efficiency is becoming much more important when comparing aeration techniques and devices. Many of the traditional aeration devices like paddlewheels and aspirator style aerators have a poor track record of reliability and higher overall energy requirements. “Aerator Graveyards” have become a common sight throughout the industry as old aeration devices are replaced and discarded year after year.

Colorite Aero-Tube™ aeration tubing can solve these problems with these distinct its advantages:

- Reduces energy costs by up to 75%

- Lack of moving parts provides a very low maintenance alternative

- Maintains higher dissolved oxygen (DO) levels

- Allows for higher stocking densities

- Allows for higher feeding rates

- Allows for more frequent feedings

- Faster Growth and reduced FCR

- Low start up cost

- Low replacement cost

Aero-Tube™ technology has been used successfully with a wide range of Aquaculture species and in a wide range of production systems. Whether you are producing shrimp or fish, anywhere you are using traditional aeration systems to oxygenate your water, you can benefit from the efficiency and durability of an Aero-Tube™ system. Aero-Tube™ Technology

When planning for the proper aeration of an aquaculture system, there are many points to consider. Please feel free to contact us and we can help design and Aero-Tube™ solution for you.

To see the many options for using Aero-Tube™ Technology please visit Aero-Tube™ Products where you will find a solution that is right for you.

Friday, August 13, 2010

Recirculation Aquaculture System(RAS) is now common in Malaysia-www.stac...

Friday, August 6, 2010

The Facts About Aeration

Surface Aerators: True surface aerators function by moving a large volume of water (800 – 1300 gpm.) a maximum of 3-4 feet into the air, thereby increasing gas transfer within the pond, inducing circulation and improving water quality. As a result of the massive amount of water being pumped into the air and splashing back down onto the water surface, a wave action radiates outward from the unit towards the pond or lake perimeter. Surface aerators are extremely effective in ponds which are less than 10 feet deep. The size, shape and depth of your water body will influence the size and quantity of surface aerators you need. A surface aeration system may be as simple as one unit or may involve several units strategically located around the water body. View our Aerator Models & Online Pricing

Surface Fountains

The primary objective of surface fountains is to create an aesthetically pleasing water feature. Similar to surface aerators, surface fountains function by pumping water into the air, thereby increasing gas transfer within the pond and improving water quality. However, a surface fountain pumps the water much higher (typically 4-15 feet), subsequently, the volume of water is significantly decreased (typically less than 250 gpm.) and, as a result, the aeration efficiency and gas transfer rates are dramatically reduced. The size and quantity of surface fountains is more often driven by aesthetics than the size, shape and depth of your water body. Often surface fountains are combined with one or more surface aerators to provide a complex water display feature while achieving superior water quality improvements. View our Fountain Models & Online Pricing

The primary objective of surface fountains is to create an aesthetically pleasing water feature. Similar to surface aerators, surface fountains function by pumping water into the air, thereby increasing gas transfer within the pond and improving water quality. However, a surface fountain pumps the water much higher (typically 4-15 feet), subsequently, the volume of water is significantly decreased (typically less than 250 gpm.) and, as a result, the aeration efficiency and gas transfer rates are dramatically reduced. The size and quantity of surface fountains is more often driven by aesthetics than the size, shape and depth of your water body. Often surface fountains are combined with one or more surface aerators to provide a complex water display feature while achieving superior water quality improvements. View our Fountain Models & Online Pricing Subsurface Aeration System As you might expect, subsurface aeration systems are entirely different from surface aerators or fountains. Rather than pumping water into the air to increase gas transfer and induce circulation, subsurface aeration systems pump air into the water. Systems of “synergistic airlift diffusers” are placed on or near the bottom of the water body. Compressed air is pumped through underwater airlines to the diffusers, bubbles out of the diffusers, and rises through the water column to the surface. As the air rises, the bubbles expand, entrain the surrounding water molecules and “pump” them towards the surface, producing a gentle boiling of water and bubbles at the surface. These systems are extremely effective in destratifying a water body. In fact, the greater the depth the more efficient the system. Subsurface aeration systems are most effective in ponds with a depth greater than 12 feet or in lakes, and are not a cost effective option for smaller water bodies. Not all aeration systems are created equal. One must closely examine actual pumping rate, oxygen transfer rate and amperage draw of the motor before making a determination as to which system to purchase. For over 50 years, the Rowledge Pond Fish Hatchery has utilized aeration units from a wide variety of manufacturers, and we have even made a few of our own. We have found the PowerHouse surface aerators and surface fountains are the most durable, efficient and effective surface aeration systems on the market. We use PowerHouse surface aerators exclusively in our hatchery facility, and are proud to be their Northeast distributor. Rowledge Pond Aquaculture can assess your pond or lake and design, build and install an aeration system for you which meets both your property management objectives as well as the ecological needs of the pond.

Thursday, August 5, 2010

Red Lobster Faring Just Fine in the Post-Spill World

It remains unclear exactly how much damage BP's oil spill will do to the aquatic life in the Gulf of Mexico, but if you're worried about one of the worst environmental disasters in decades cutting into your $11.99 "festival of shrimp," you can rest easy. It turns out some of the country's most popular seafood restaurants have placed more emphasis on the second syllable of "seafood" rather than the first.

According to Rich Jeffers, a spokesman for Red Lobster, the casual-dining seafood chain gets very little of its shrimp from the gulf—or any ocean for that matter. Instead, it grows "farm-raised" shrimp in ponds throughout South America and Asia (Jeffers mentioned Thailand specifically), and at any given moment, the company has enough shrimp to meet the demand of all 700-plus of its locations worldwide for at least six months.

Of course, maintaining such a large shrimp supply isn't easy. In order to keep so many crustaceans alive in the densely populated farms—there can be up to 170,000 shrimp larvae in a single pond an acre wide and a couple meters deep—antibiotics are pumped into the water. Environmentalists have decried such practices, arguing that they can be harmful to the local ecosystems, but Jeffers says all their farms are closely inspected and certified by the Aquaculture Certification Council.

"What I would point out to you is the benefit of seafood sustainability," he says. "We're able to provide shrimp year-round, not relying on harvesting them from the ocean, which can only meet a certain demand."

Long John Silver's, the national fast-food chain, was not so forthcoming about the source of its shrimp, but it did tell NEWSWEEK in a short e-mail that is "not affected" by the oil spill.

So breathe a sigh of relief, cheap-fish lovers! Just as there is no end in sight to the consequences for the gulf, your endless shrimp platters will indeed remain endless.

A circulation model to investigate the movement of wastes from an Open ocean aquaculture site

David W. Fredriksson*, James D. Irish, Dale A. Kiefer, Jack Rensel, and Frank OBrien

Department of Naval Architecture and Ocean Engineering,

United States Naval Academy

590 Holloway Road 11D, Annapolis, MD 21402

USA

fredriks@usna.edu A numerical circulation study of the western Gulf of Maine was conducted to investigate the movement of wastes from an open ocean aquaculture site. To examine the hydrodynamics of the region, a domain was built with the ADvance CIRCulation model with Gulf of Maine bathymetry, shoreline, island and open ocean boundary conditions. At the open boundaries, the model was forced with dominant tidal elevation components, including the M2, S2, N2, K1, O1 constituents, representing possible low flow conditions. These conditions are with no weather forced or geostrophic currents to further diffuse and advect material from the site, but just the regular tidal motions. Model predictions were compared with surface elevation and Acoustic Doppler Current Profiler (ADCP) measurements from a moored instrumentation platform at the aquaculture site. At the site, the ADCP collected velocity data sets oriented in the east-west, north-south and vertical directions at nineteen, 2 meter depth bins. The data sets were processed to obtain the velocity tidal components and reconstructed to form a time series. The reconstructed time series was then compared with the model results. Differences between the model and measured results were on the order of cm s-1

The numerical flow values from the large model domain were then used as input to the program AquaModel. AquaModel is a GIS tool that provides three-dimensional simulation of growth and metabolic activity of penned fish as well as the associated flow and transformation of nutrients, oxygen and particulate wastes in adjacent waters and sediments. AquaModel can be used to examine both the near and far field affects of individual or clusters of fish cages. The information can then be used to effectively site new farms, evaluate operation techniques, and plan monitoring programs.

Environmental Observations in support of Physical and Biological Modeling of Aquaculture Sites

University of New Hampshire, Jere Chase Ocean Engineering Laboratory

24 Colovos Rd., Durham, NH 03824

jirish@whoi.edu Optimum design of an aquaculture operation depends on environmental conditions at the site, and requires a combination of observations, hydrodynamic modeling, and biological modeling. To develop and demonstrate this approach, a study was conducted for an aquaculture site in the Western Gulf of Maine about 12 km off the coast of New Hampshire in a depth of 50 m of water. The University of New Hampshire has been conducting open ocean aquaculture research at this site for nearly 10 years (http://ooa.unh.edu/). The research included measuring physical, chemical, and biological parameters important for aquaculture operations. Moored time series were made for about 9 months a year, and discrete water samples were taken monthly from spring to fall at the site starting in 1999 and continuing into 2008. Also, the UNH Coastal Ocean Observing Center has been monitoring the ecosystem in the region with monthly cruises. Their results supply additional information on the biological and chemical properties at the site. All these data are used for initializing and forcing the hydrodynamic model (ADvance CIRCulation = ADCIRC) and biological model (AquaModel).

The moored instrumentation measured water current profiles, temperature and salinity at the surface, mid-water (the 22 m depth of the fish cages), and near the bottom. Also, moored mid-water and bottom observations were made of dissolved oxygen, chlorophyll-a and turbidity. These observations provided information on oscillatory tidal currents (0.1 m/s oriented perpendicular to the coast) that help disperse waste products. Weather forced currents that advect material off site were quite variable with maxima of 0.5 m/s oriented along shore. These current observations were used to validate the ADCIRC tidal model (whose results were used to force AquaModel), and the currents also directly forced AquaModel.

The temperature and salinity follow a yearly cycle of warming in the spring-summer, and cooling in the fall-winter. Fall storms cause full water column mixing from early winter through early spring when thermal stratification is established, preventing vertical mixing. Temperatures cool to 2 to 4C in the winter and bottom waters warm to 10C in the summer while surface waters reach 22C. River runoff freshens the water in spring into summer to about 31 PSU with storm runoff spikes in surface waters reaching the low 20s. With the winter mixing, the water column salinity increases to above 33 PSU. Oxygen profiles are saturated or supersaturated from surface to bottom in the winter, but with the onset of spring stratification, oxygen below the pycnocline steadily decreases from fully saturated to about 70% saturated by the end of summer. The mid-water oxygen remained saturated into the summer, then also decrease into the 70% range by the end of summer. Suspended sediment and chlorophyll time series and discrete sample show river runoff sediments, spring and fall chlorophyll blooms. Red-tide blooms are also observed consuming oxygen. These water quality results were summarized into weekly averages and used to initialize and drive AquaModel studies of the site.