Aquafloat Induced Air Flotation (IAF) aerators & associated plant from PCPL provide an efficient & cost effective air flotation system for the removal of fats, oils, greases and other solids from industrial & municipal water and wastewater.

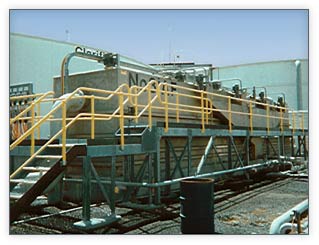

Aquafloat: The aquafloat in action Aquafloat is also suitable for the thickening of sludges from other water & wastewater treatment processes. Aquafloat is also suitable for the efficient diffusion of externally supplied gases (such as ozone or nitrogen) into liquid. Aquafloat can provide an effective and simple alternative to more traditional dissolved air flotation (DAF) plants. Operation The range is based around the Aquafloat IAF microbubble aerators. These aerators are capable of inducing large volumes of atmospheric air (or introduced gas) and presenting it via a specially designed rotating disc into a vessel or body of liquid as extremely fine microbubbles. These microbubbles effectively attach to solids particles in the liquid and float them gently to the surface of the liquid for concentration and mechanical removal, allowing clarified liquid to pass out of the vessel to discharge or further treatment. This aeration function is performed with very little induced turbulence making the Aquafloat an excellent unit for flotation applications. Simplicity Unlike more traditional DAF aeration, the Aquafloat aerator produces it’s air via atmospheric induction at atmospheric pressure. As such, there is no need for pressure vessels, recycle pumps and associated pipework and controls. System Sizing Aquafloat systems based around the Aquafloat aerators have been made to treat as little as a few hundred litres per day in a small tank, right up to single vessels treating 10 megalitres per day in large industrial oil refinery applications. Retrofit Capability and Flexibility The Aquafloat range of IAF aerators lend themselves to retrofit applications very readily. Where there is an underperforming DAF or existing flotation plant, a simple Aquafloat aerator installation can boost it’s operation immediately at low expense. This can mean immediate savings in operating consumables and discharge costs. Likewise, existing pits and separation vessels or clarifiers can be very quickly turned into flotation cells by the simple introduction of an Aquafloat IAF aerator or aerators. Multicell High Flow Units The Aquafloat has been particularly successful in very high flow applications such as oil refinery wastewater applications. This is effected by a special multi flotation cell plant design allowing for in-line controllable air quality in a number of sequential flotation cells. These systems can be provided to the very high specifications required by the oil and gas industry. Low Noise Operation The Aquafloat aerators are very quiet units, with aeration activity taking place below the surface of the liquid in any installation.No noisy air compressors are required for Aquafloat aeration. Australian Made - World Class The Aquafloat range is designed and manufactured wholly within Australia with local parts support – and has been exported all over the world. For further information or an application design using Aquafloat – please contact PCPL or your local Aquafloat representative.

No comments:

Post a Comment